ELGi's PRECISION MACHINING -

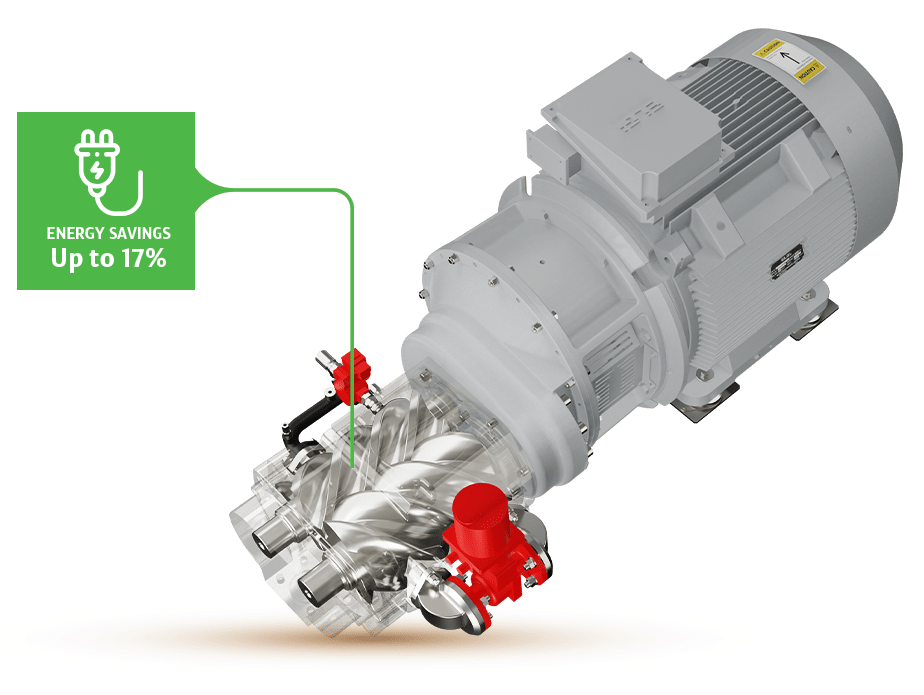

During the 1990s, customers were looking for compressors that could supply greater volumes of air; something piston compressors could not fulfill. With that began our efforts to manufacture screw compressors in-house. A tall order indeed, given that designing airends involves the development of a complex mathematical formula to define the profiles of the screw while manufacturing airends demands high precision machining with very close tolerance bands in microns. Over the past 30 years, ELGi built its knowledge of “know-how” and “know-why” of compressors to become one of the five companies in the world with the capability to design and manufacture its own airends.

In 2011-12, the Air Compressor Plant was established on over 100 acres at Kinathukadavu, near Coimbatore, India, incorporating some of the best practices in airend manufacturing globally. The state-of-the-art plant is equipped with high-precision grinding, milling, and turning machinery, with a few critical machines built by the ELGi machine-building team. The facility is also installed with mixed model conveyorised assembly lines, a vertical storage and retrieval system, a metrology laboratory, and testing equipment, ensuring high accuracy and reliability.

Keywords

state

India

world

1990s

milling

microns

airends

efforts

profiles

facility

knowledge

art plant

something

customers

100 acres

tall order

Coimbatore

capability

development

reliability

past 30 years

high accuracy

Kinathukadavu

best practices

five companies

greater volumes

retrieval system

vertical storage

screw compressors

turning machinery

testing equipment

critical machines

piston compressors

metrology laboratory

Air Compressor Plant

airend manufacturing

close tolerance bands

high-precision grinding

high precision machining

ELGi machine-building team

complex mathematical formula

mixed model conveyorised assembly lines