ELGi's Oil Lubricated Screw Air Compressor Maintenance Tips -

Oil lubricated air compressors are commonly used in various industries for generating compressed air. Proper maintenance of these compressors is essential to ensure their efficiency, longevity, and safe operation. Here are some maintenance tips to keep your oil lubricated compressor in optimal condition:

Regular Oil Checks - Check the compressor’s oil level frequently. Low oil levels can cause excessive friction and lead to premature wear of components. Be sure to use the recommended type and grade of oil specified by the manufacturer.

Oil Changes - Regularly change the compressor’s oil as per the manufacturer’s guidelines. This ensures the oil’s lubricating properties remain effective and prevents contaminants from building up.

Air Filter Inspection and Replacement - The air intake filter prevents dust, debris, and other contaminants from entering the compressor’s system. Check the air filter regularly, clean it, and replace it if it’s damaged or clogged. A clogged filter can restrict airflow and decrease the compressor’s efficiency.

Cooling System Maintenance: The compressor’s cooling system is essential to prevent overheating. Clean the cooling fins and ensure proper airflow to dissipate heat effectively. Additionally, check for any coolant leaks and address them promptly.

Inspect Belts and Hoses - Check the condition of the belts and hoses that drive the compressor. Replace any worn-out or damaged belts and hoses to maintain smooth operation.

Drain Condensate - Condensation can accumulate in the compressor’s tank and lines. Drain the condensate regularly to prevent corrosion and water damage to internal components.

Professional Services from ELGi - While some maintenance tasks can be performed in-house, it’s advisable to have an authorised technician from ELGi conduct periodic inspections and servicing of your oil injected air compressor. They can identify potential issues early on and address them appropriately. Schedule an appointment with our experts and get your compressed checked.

Oil Lubricated Rotary Screw Technology - Enhancing Industrial Performance -

Learn more about ELGi’s air compressors – its operations and how it ensures you get the best value for your investment. (VIDEO)

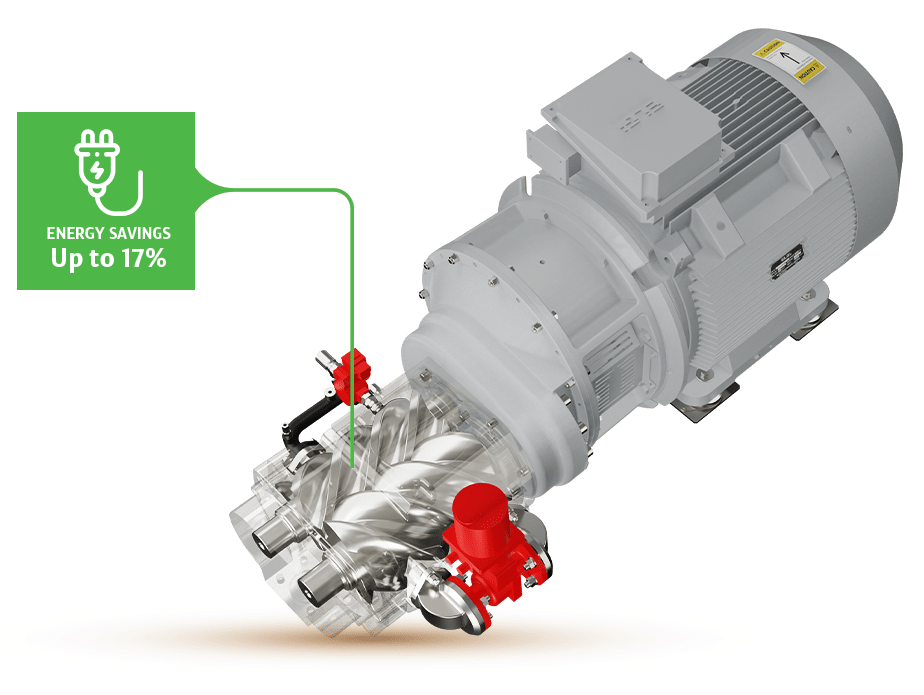

ELGi's EG series rotary screw air compressors are used by plant managers across the globe and experience the desired performance, and post sales experience. The EG series compressors, with their compact design provide reliable solutions for a wide range of industrial applications.

Keywords

wide range

best value

Oil Changes

water damage

cooling fins

coolant leaks

proper airflow

compact design

plant managers

premature wear

safe operation

clogged filter

compressed air

Low oil levels

Drain Condensate

potential issues

smooth operation

optimal condition

maintenance tasks

air intake filter

other contaminants

reliable solutions

excessive friction

various industries

Proper maintenance

Regular Oil Checks

internal components

desired performance

periodic inspections

authorised technician

Professional Services

post sales experience

Air Filter Inspection

Industrial Performance

lubricating properties

industrial applications

The EG series compressors

Cooling System Maintenance

oil injected air compressor

Oil lubricated air compressors

Oil Lubricated Rotary Screw Technology

EG series rotary screw air compressors

Oil Lubricated Screw Air Compressor Maintenance Tips