ELGi Oil-free compressed air solutions are used extensively in the pharmaceutical, textile & automotive industries.

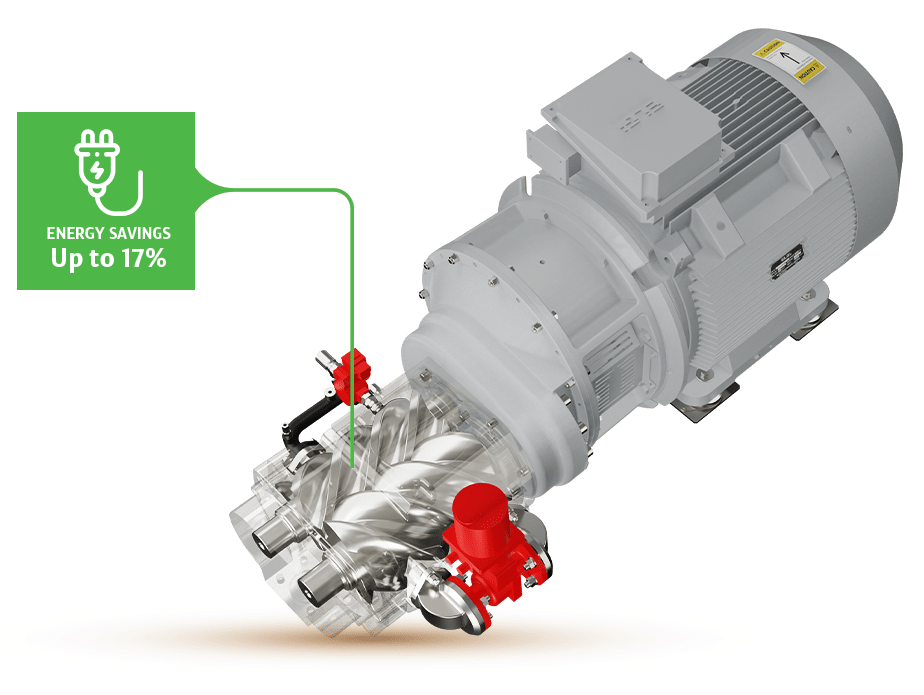

This inventive machine uses no lubricating oil in the compression chamber and hence delivers compressed air with practically no trace of oil. Additionally, because of the continuous sweeping motion of the screws – two meshing helical screws known as rotors, driven by a pair of timing gears – there is very little pulsation or surging of flow, which occurs with piston compressors. Screw compressors thus deliver smooth, pulse-free compressed air. They also tend to be compact and run smoothly with minimal vibration. Since they also employ a more efficient compression system, they not only reduce energy costs but also enable precise adaptation to end-user requirements based on careful study and analysis of their critical processes and customising with a controlled, total compressed air system, thereby also improving productivity.

Keywords

flow

pair

trace

rotors

surging

textile

analysis

productivity

timing gears

energy costs

careful study

lubricating oil

little pulsation

minimal vibration

inventive machine

Screw compressors

piston compressors

precise adaptation

critical processes

compression chamber

end-user requirements

automotive industries

continuous sweeping motion

two meshing helical screws

efficient compression system

smooth, pulse-free compressed air

ELGi Oil-free compressed air solutions

controlled, total compressed air system