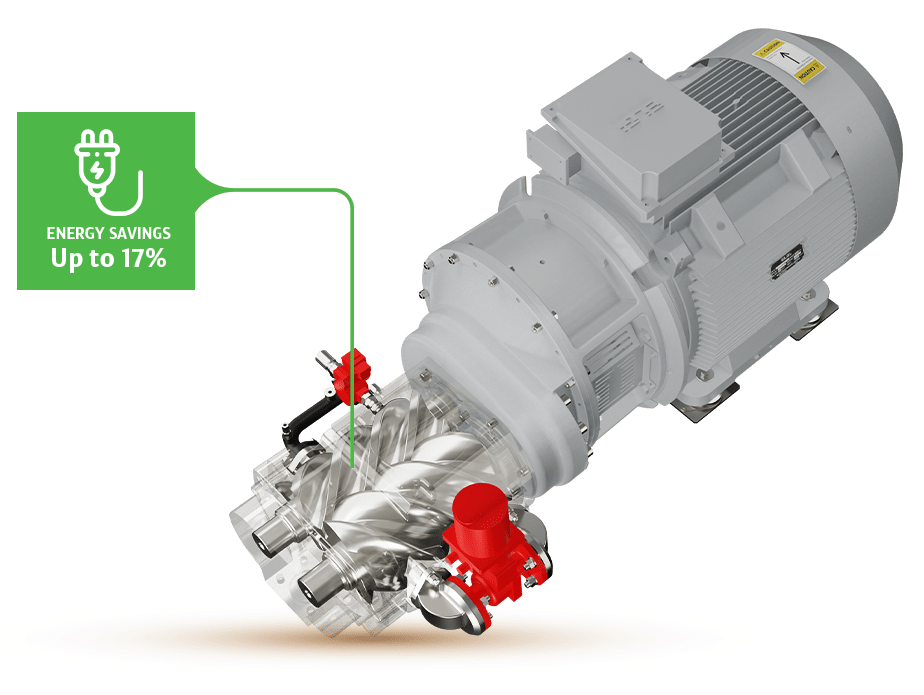

ELGi CONSERVE drives match output with demand by varying motor speed, the power consumption reduces in line with the reduction in demand. This helps in eliminating the frequent load-unload cycle and also the wasted power from the energy bill. A fixed speed compressor operates on a load-unload band of at least 10 PSI around the working pressure whereas with ELGi VFD, compressor can be operated within a band of 2 PSI. Since compressors are not operated under higher than working pressure requirements, there is a substantial saving of 1% power saving for every 2 PSI reduction in operating pressure. In a fixed speed compressor with star-delta starter, starting current is as high as three times the full load current(FLC). With ELGi VFD starting, starting current is as equal to the full load current (FLC). This helps to avoid using heavy rated components like fuses, MCCB, cable size, generator rating, isolators etc. For compressed air systems with fluctuating demand pattern, return on investment due to power saving will be less than 12 months.

Keywords

FLC

MCCB

line

fuses

output

return

10 PSI

ELGi VFD

12 months

isolators

investment

cable size

energy bill

compressors

1% power saving

2 PSI reduction

starting current

load-unload band

generator rating

full load current

power consumption

star-delta starter

operating pressure

substantial saving

varying motor speed

ELGi CONSERVE drives

fixed speed compressor

compressed air systems

heavy rated components

fluctuating demand pattern

frequent load-unload cycle

working pressure requirements