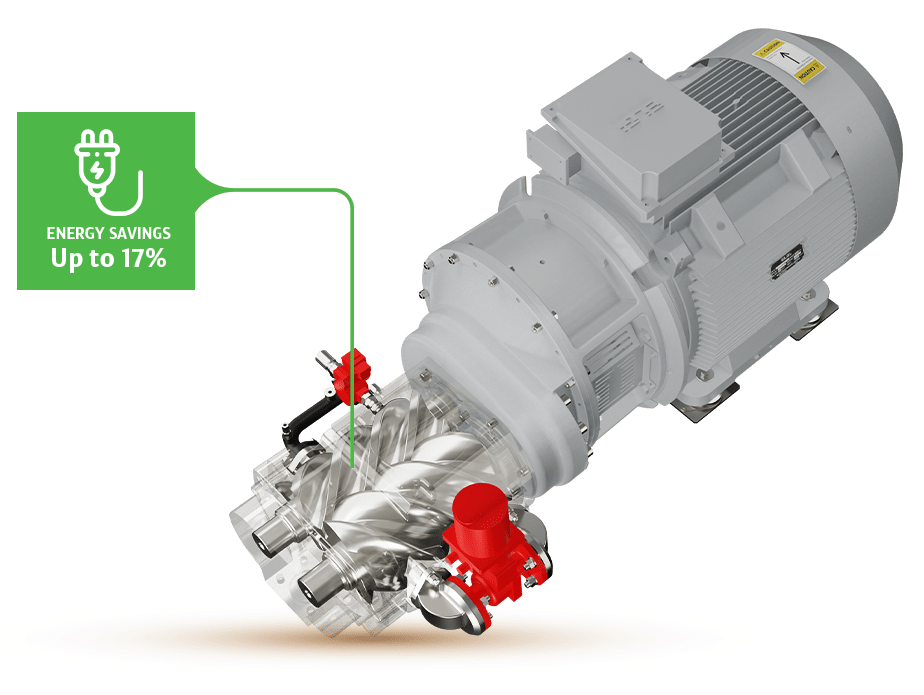

ELGi CONSERVE aligns output with demand by adjusting motor speed, resulting in a decrease in power consumption corresponding to the lower demand. This assists in removing the constant load-unload cycle and the unnecessary power usage from the energy expenses. A fixed speed compressor functions within a load-unload range of at least 10 PSI around the operating pressure, whereas the ELGi VFD compressor can operate within a 2 PSI band. As compressors do not function above their required working pressure, a significant energy saving of 1% occurs for every 2 PSI decrease in operating pressure. In a constant speed compressor utilizing a star-delta starter, the starting current can be up to three times the full load current (FLC). With ELGi VFD starting, the starting current matches the full load current (FLC). This assists in preventing the use of heavily rated parts such as fuses, MCCB, cable dimensions, generator capacity, isolators, etc. In compressed air systems with varying demand patterns, the return on investment from power savings will be under 12 months.

Keywords

12 months

1 occurs

10 psi

2 psi decrease

2 psi band

stardelta starter

lower demand

power savings

operating pressure

power consumption

loadunload range

energy expenses

starting current

varying demand patterns

starting current matches

required working pressure

unnecessary power usage

significant energy saving

constant loadunload cycle

elgi vfd starting

compressed air systems

heavily rated parts

elgi vfd compressor