USING AIR COMPRESSORS FOR THE AUTOMOTIVE INDUSTRY -

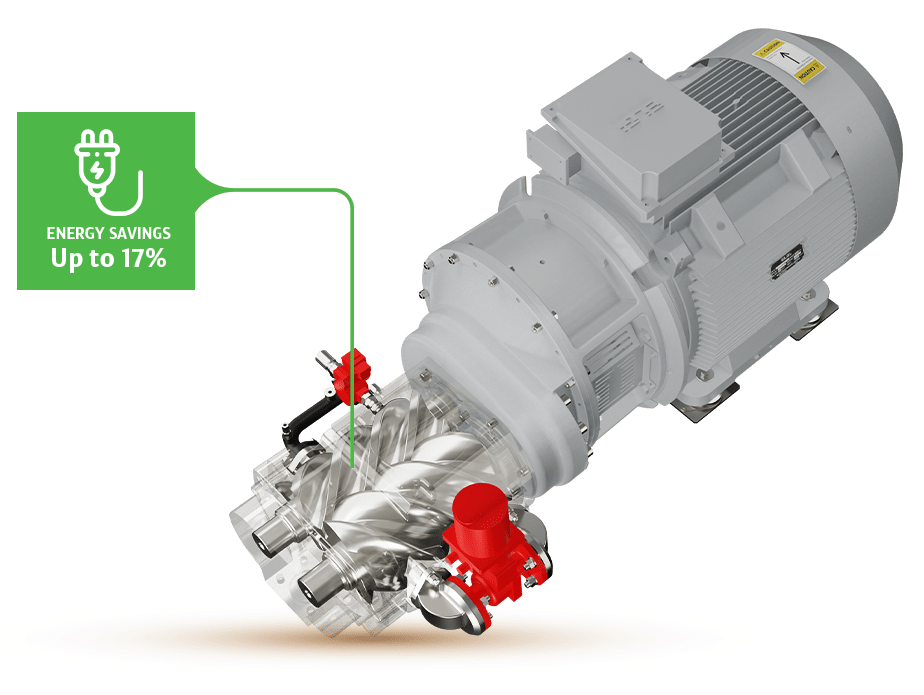

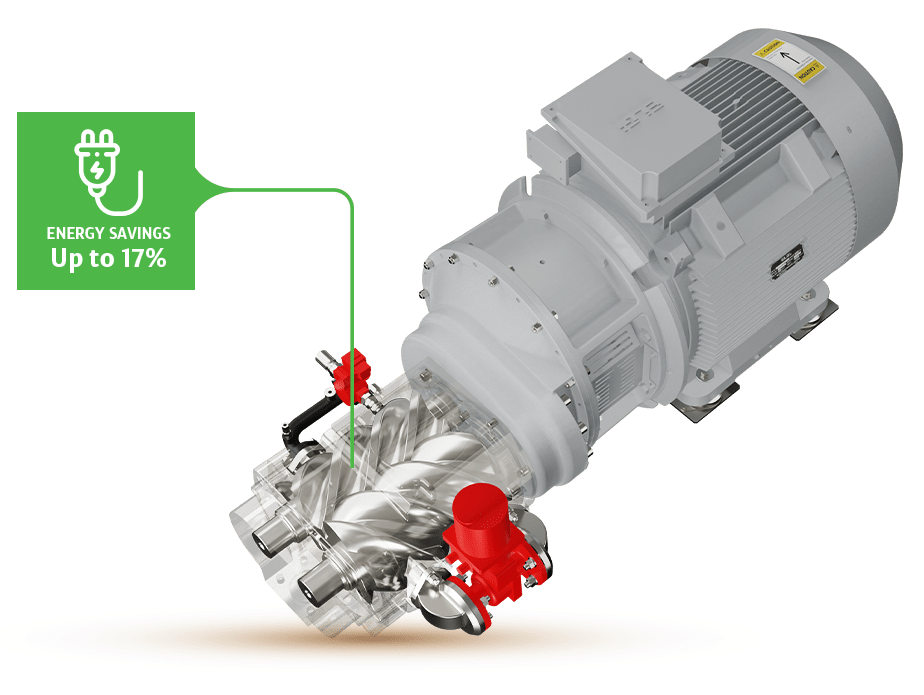

1) Plasma Cutting – As the compressed air is forced into the chamber containing a plasma electrode and a plasma cutting tip, an electric arc is struck between them. This arc “Plasma rises” the compressed air, making it electrically conductive, which then escapes the pressurised chamber via a small hole in the Plasma Cutting tip, taking the energy of the arc with it. The heat of the Plasma Arc melts the metal to be cut while the force of the air blows it away. ELGi’s rotary screw air compressor comes with a six years warranty on the airend, thus promising the durability of the compressor.

2) Air- operated Robots – With the advancement in robotics, almost all of the strenuous work done earlier by humans is now carried out by air-operated robots. They are called air-operated because of the abundant use of pneumatic pistons on the arms of these robots. From picking heavyweights to tightening nuts and bolts, everything can be performed by the air-operated bots. Air compressors for auto shops offered by ELGi are perfectly suited to operate these machines in the automotive manufacturing industry.

3) Tyre Inflation – Upon close observation at any gas station, an air compressor can be spotted. The air compressor used at gas stations fulfils the basic requirement of any car, which is the air in the tires. Compressors make tire inflation easy and help maintain the safety and reliability of your automobile.

4) Automobile Finishing – Automotive finishing is one of the most important steps of auto manufacturing. The paint and clear coat serve as protective coatings to shield the vehicle from the external elements. Improper automobile finishing leads to the formation of thin films, dry spay, crater, bubble, and ripples, which further weakens the paint, and the automobile becomes vulnerable to rust and decay.

5) Air Tools - Many garages are now shifting to air tools powered by compressed air, such as an air compressor for automotive tools, due to their increased efficiency compared to traditional electric-powered tools. One of the significant advantages of using pneumatic tools over electric tools is them being lightweight with lower operating costs.

Keywords

THE

car

arms

rust

heat

ELGi

nuts

metal

force

bolts

decay

paint

tires

airend

safety

bubble

energy

crater

humans

ripples

vehicle

dry spay

machines

robotics

formation

Air Tools

auto shops

small hole

clear coat

thin films

everything

durability

Plasma Arc

advancement

gas station

reliability

electric arc

heavyweights

Many garages

abundant use

compressed air

electric tools

strenuous work

tire inflation

Tyre Inflation

AIR COMPRESSORS

pneumatic tools

important steps

plasma electrode

automotive tools

basic requirement

close observation

air-operated bots

pneumatic pistons

external elements

auto manufacturing

plasma cutting tip

six years warranty

AUTOMOTIVE INDUSTRY

air-operated robots

pressurised chamber

protective coatings

Automotive finishing

increased efficiency

Air- operated Robots

lower operating costs

significant advantages

rotary screw air compressor

Improper automobile finishing

automotive manufacturing industry

traditional electric-powered tools