The key difference between Rotary Screw Air Compressors and Reciprocating Air Compressors is the mechanism in which they compress air.

Their distinct features can be understood in terms of:

1) System design

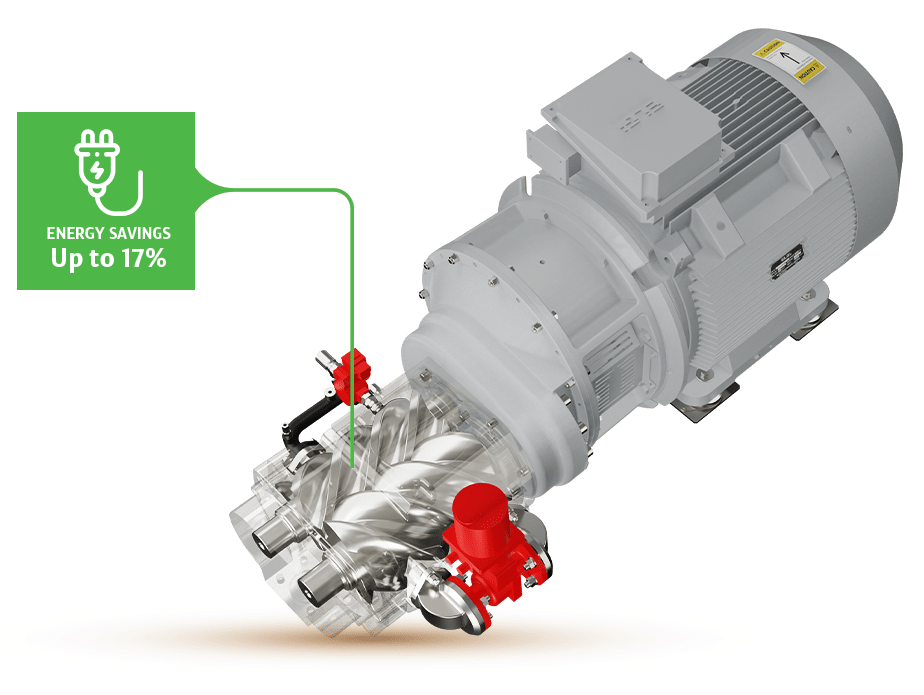

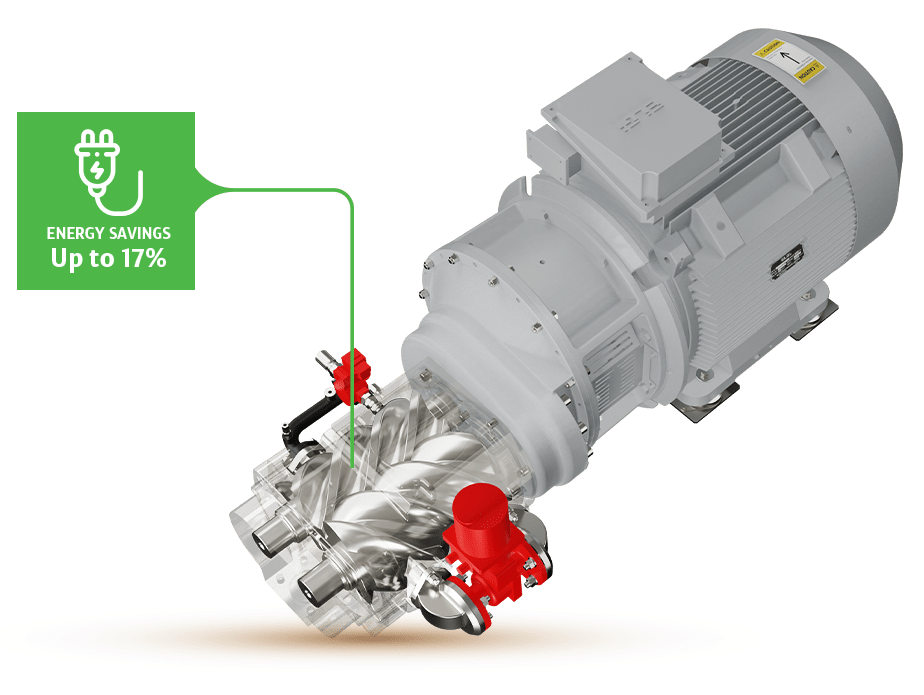

Rotary screw air compressors have a couple of meshing spiral screws called rotors for compressing the input air. While reciprocating air compressors employ pistons moved by a crankshaft for compressing the air.

2) Components involved

With just two moving parts (screws) that have a small gap between them, screw air compressors are not subject to much wear and tear. Even in models where the two screws come in contact with each other, they don’t encounter any friction, which is why they are less likely to break down.

On the other hand, reciprocating air compressors have several moving parts like pistons, piston rings, connecting rods, and inlet-outlet valves due to which they are noisier and may need stocking of spares.

3) Temperature

The internal heat produced by screw air compressors during operation is between 80 - 99 degrees celsius. The heat production is limited, as there is no friction between the screws. The oil or lubricant used between the rotors and casing creates a non-wearing seal that can eliminate the heat with the help of a thermostatically managed fluid circuit.

In reciprocating air compressors, the pistons operate at temperatures between 150-200 degrees celsius. The high temperatures are due to the friction caused by the movement of piston rings against the cylinder walls.

4)Oil filtration

The chances of finding residual oil in an oil-lubricated screw air compressor are very low, because this unit has a three-stage oil filtration system. The oil content is typically below three particles per million (PPM).

However, a reciprocating air compressor does not have an oil filtration system, which is why, its outlet air can be more contaminated than a screw air compressor. The oil content in the air also increases when piston rings and oil rings deteriorate, allowing oil to move up to the compression side.

Individual benefits of both the models -

The top advantages of choosing a screw air compressor are:

1) Continuous air supply

2) Higher duty cycle

3) Better durability

4) Higher overall efficiency

5) Lower ambient noise

6) Higher airflow per rated power

Few reasons why some operators still prefer a reciprocating air compressor are:

1) Very high pressure requirements

2) Spare parts management

3) Lower duty cycle

Keywords

PPM

unit

help

rods

tear

power

terms

models

couple

spares

rotors

casing

contact

chances

pistons

stocking

friction

movement

small gap

mechanism

oil rings

operators

input air

operation

lubricant

two screws

Components

other hand

crankshaft

outlet air

oil content

Few reasons

residual oil

piston rings

wearing seal

internal heat

fluid circuit

System design

cylinder walls

top advantages

key difference

Higher airflow

three particles

150-200 degrees

80 - 99 degrees

heat production

compression side

thermostatically

Lower duty cycle

two moving parts

Higher duty cycle

Better durability

high temperatures

distinct features

Individual benefits

Lower ambient noise

inlet-outlet valves

several moving parts

Continuous air supply

meshing spiral screws

Spare parts management

Higher overall efficiency

Rotary Screw Air Compressors

reciprocating air compressor

Very high pressure requirements

three-stage oil filtration system

oil-lubricated screw air compressor