Aluminium is ‘AIR’ to stay!

We live in a world of compressed air wonders and aluminium!

There was a time when aluminium was considered so valuable that royals preferred using it for plates and cutlery, over those made of gold and silver! In fact, it is the most abundant metal on the earth’s crust. However, it is rarely found in its pure form naturally. The chief source of aluminium is bauxite ore, which was discovered in 1821 by P. Berthier. He found a hard, reddish, clay-like material (one that contained 52% aluminium oxide) near the village of Les Baux in southern France. Berthier named it bauxite after the village.

Years later in 1886, Charles Martin Hall made a discovery in Ohio. At the same time, metallurgist Paul Louis Toussaint Héroult made the same discovery in Gentilly. Both men dissolved aluminium oxide in molten Cryolite and extracted the aluminium through electrolysis. This came to be known as the Hall-Héroult electrolytic method and was economically viable too.

In the year 1888, Carl Josef Bayer, son of the founder of Bayer Chemical Company, invented an improved process for making aluminium oxide, known as the Bayer process. Within the next two years, the first aluminium companies were founded in France, then in the USA followed by Switzerland. By 1890, its cost had tumbled nearly 80%!

Australia, Guinea and Jamaica account for 60% of world’s bauxite output, with Guinea contributing nearly 50% of the total reserve! Bauxite ore is mined primarily in Australia, Africa, South America and the Caribbean. India too is naturally endowed with large deposits of bauxite, and ranks as the fifth largest alumina producer in the world.

Aluminium has a variety of uses in our daily life. Starting from everyday utensils to the CDs that were so popular until a few years back, window frames to air planes and even the foil that we wrap food in, it’s all made of aluminium. Compressed air plays a crucial role in the process of producing aluminium. Right from the mines to the operating pneumatic components of mining equipment and even the casting process for operating specialised equipment and actuators, all require compressed air.

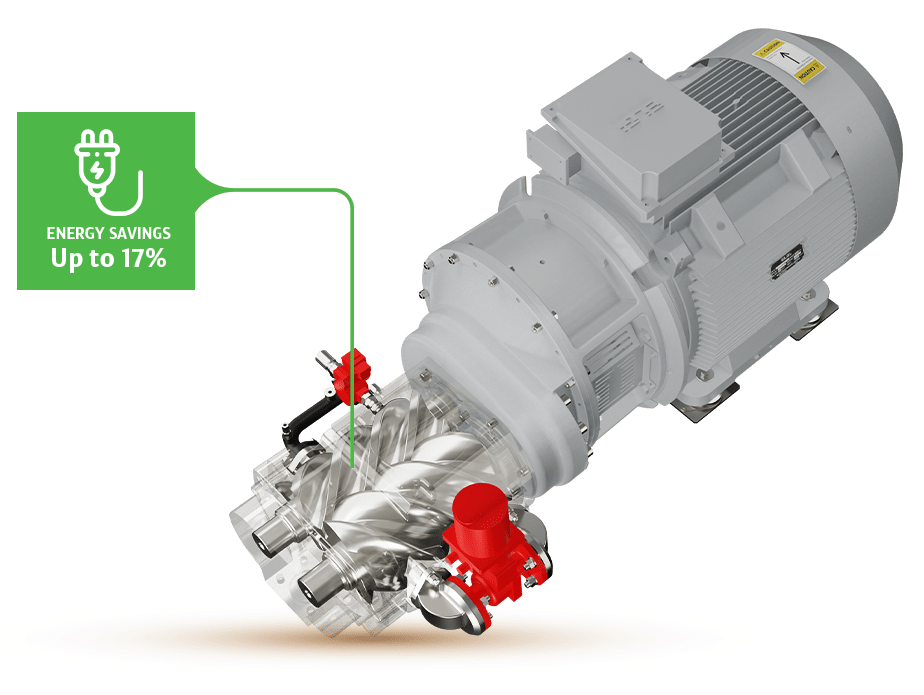

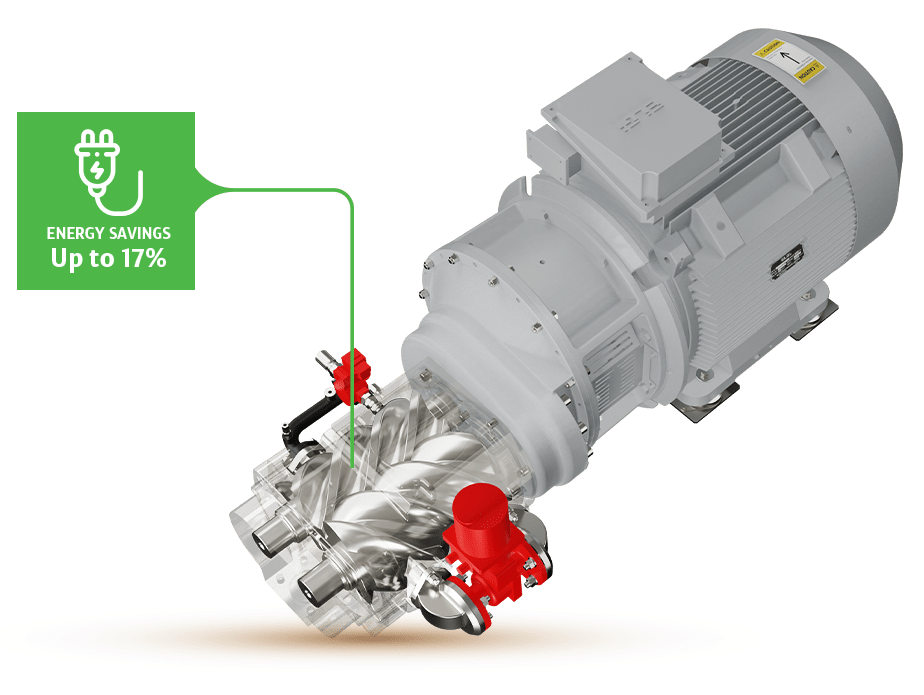

Different types of ELGi air compressors have been increasingly used in this industry, from small private smelters to government-owned integrated aluminium companies. They operate creditably under demanding and trying conditions. National Aluminium Company Ltd (NALCO), located in Angul, Odisha for instance, uses ELGi’s high-pressure compressors in its smelter unit, and to actuate pneumatic equipment in other operational areas.

Compressed air is also used at various stages in the manufacturing of cables and wires. Pneumatically operated brake drums are employed to stop the fast rotating bunching machines. ELGi’s compressors are widely used by cable manufacturers all over India. KEI, a leading cable manufacturer located in Bhiwadi, Rajasthan uses a number of these compressors.

Keywords

village years

world aluminium

rarely found

producing aluminium

aluminium companies

casting process

bayer process

improved process

bauxite ore

bhiwadi rajasthan

india kei

cable manufacturers

smelter unit

angul odisha

nalco located

operate creditably

crucial role

wrap food

everyday utensils

large deposits

caribbean india

mined primarily

guinea contributing

jamaica account

80 australia guinea

economically viable

molten cryolite

les baux

chief source

earths crust

abundant metal

royals preferred

air planes

naturally endowed

mining equipment

making aluminium oxide

elgi air compressors

worlds bauxite output

elgis highpressure compressors

require compressed air

compressed air wonders

pure form naturally

actuate pneumatic equipment

operating specialised equipment

small private smelters

operating pneumatic components

daily life starting

largest alumina producer

hallhéroult electrolytic method